How Does a Packing Gland Work on a Split Case Pump, and How Do You Adjust It Properly?

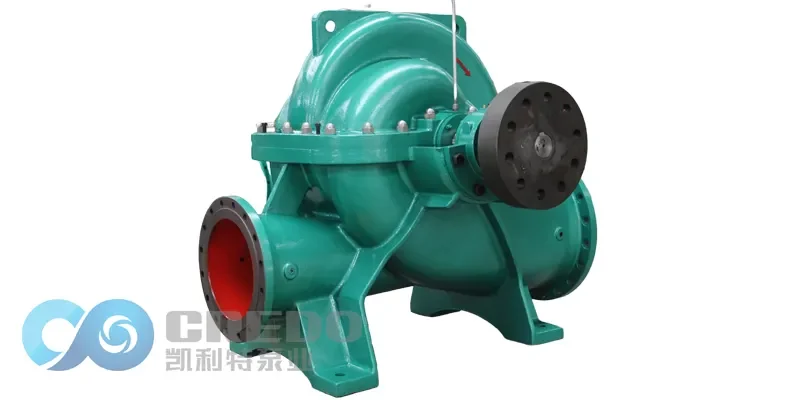

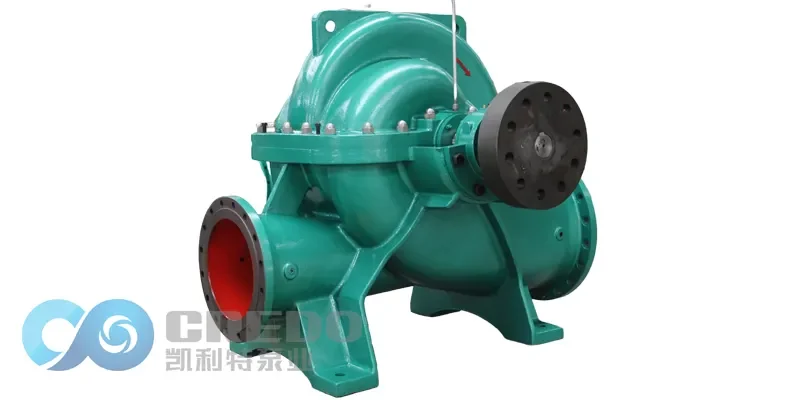

Split case pumps are widely used in water supply, HVAC, power plants, and industrial systems. One of their most reliable and cost-effective sealing solutions is the packing gland (stuffing box).

Unlike mechanical seals, packing glands rely on controlled leakage to achieve sealing, lubrication, and cooling.

Understanding how packing glands work—and how to adjust them correctly—is essential for pump reliability, shaft protection, and long service life.

1. How a Packing Gland Works: The Principle of Controlled Leakage

Packing glands do not aim for zero leakage. Instead, they use controlled seepage to lubricate and cool the shaft while restricting excessive fluid loss.

Table 1: Working Mechanism of a Packing Gland

| Step | Component / Action | Function |

| 1 | Packing rings installed in stuffing box | Surround the shaft to form the sealing medium |

| 2 | Gland follower tightened | Axially compresses packing rings |

| 3 | Packing deformation | Expands radially against shaft and stuffing box |

| 4 | Micro leakage paths form | Allow limited fluid seepage |

| 5 | Controlled leakage | Provides lubrication, cooling, and sealing assistance |

Why Leakage Is Essential

Lubrication: Prevents dry friction and shaft damage

Cooling: Removes heat from friction zone

Sealing: Limits leakage to a safe, manageable rate

Pressure-assisted sealing: Internal pressure pushes packing tighter against the shaft

A visible drip is normal—and necessary.

2. Why Packing Glands Are Used on Split Case Pumps

Packing glands remain popular on split case pumps due to their robustness and serviceability, especially in large or demanding installations.

Table 2: Advantages of Packing Glands on Split Case Pumps

| Advantage | Explanation |

| Robust & tolerant | Handles minor shaft misalignment and vibration |

| Easy maintenance | Repacking without pump disassembly |

| Lower cost | Lower initial cost than mechanical seals |

| Wide material range | Suitable for abrasive, hot, corrosive, or dirty fluids |

| Forgiving operation | Minor adjustments can restore sealing |

3. Main Components of a Packing Gland System

Table 3: Packing Gland Components and Functions

| Component | Function |

| Packing rings | Create the sealing interface |

| Stuffing box | Houses the packing |

| Gland follower | Applies compression force |

| Gland studs & nuts | Allow controlled adjustment |

| Shaft sleeve | Protects shaft from wear |

| Lantern ring (optional) | Allows external flush injection |

Engineering note:

In many split case pumps, packing seals against a replaceable shaft sleeve, not the shaft itself—critical for long-term reliability.

4. How to Achieve Proper Packing Adjustment (Critical Section)

Always adjust packing while the pump is running at operating temperature and pressure.

Target Leakage

Typical guideline: 5–60 drops per minute

Higher pressure or speed → slightly higher leakage required

Zero leakage = over-tightening and failure risk

Step-by-Step Adjustment Procedure

Table 4: Proper Packing Adjustment Procedure

| Step | Action | Key Notes |

| 1 | Observe initial leakage | Slightly higher leakage acceptable during break-in |

| 2 | If dry or hot → loosen | Loosen nuts evenly (≈1/8 turn) |

| 3 | If leaking too much → tighten | Tighten gradually and evenly |

| 4 | Wait after each adjustment | 10–20 minutes for stabilization |

| 5 | Achieve stable drip rate | Uniform around shaft circumference |

| 6 | Final check | Nuts snug, not over-compressed |

Temperature guideline:

Gland temperature should stay below ~65°C (150°F).

Steam or boiling water at the gland indicates severe overheating.

5. Common Adjustment Mistakes to Avoid

Table 5: Common Packing Gland Errors

| Mistake | Consequence |

| Over-tightening to stop leaks | Burned packing, shaft sleeve damage |

| Uneven tightening | Local overheating and leaks |

| No visible leakage | Loss of lubrication and cooling |

| Rushing adjustments | Premature failure |

| Wrong packing material | Rapid wear or chemical attack |

6. Best Practices for Long-Term Reliability

Table 6: Packing Gland Best Practices

| Area | Recommendation |

| Packing selection | Match fluid, temperature, pressure, and speed |

| Installation | Cut rings square, stagger joints 90° |

| Tightening | Use cross-pattern tightening |

| Flushing | Use lantern ring for abrasive or hot fluids |

| Monitoring | Periodically check leakage and temperature |

| Repacking | Required if leakage keeps increasing despite tightening |

7. When Should Packing Be Replaced?

Repacking is necessary when:

Leakage increases continuously

Frequent tightening is required

Packing overheats despite proper adjustment

Packing material shows visible degradation

Conclusion: Controlled Leakage = Reliable Sealing

The packing gland on a split case pump is not a primitive seal, but a proven, highly adaptable solution when correctly understood and adjusted.

Key takeaway:

A slight, visible drip means the packing is working correctly.

A dry, overheated gland signals imminent failure.

By respecting the principles of controlled leakage, correct material selection, careful installation, and patient adjustment, operators can:

Extend packing life

Protect shaft sleeves

Maintain stable pump operation

Reduce unplanned downtime