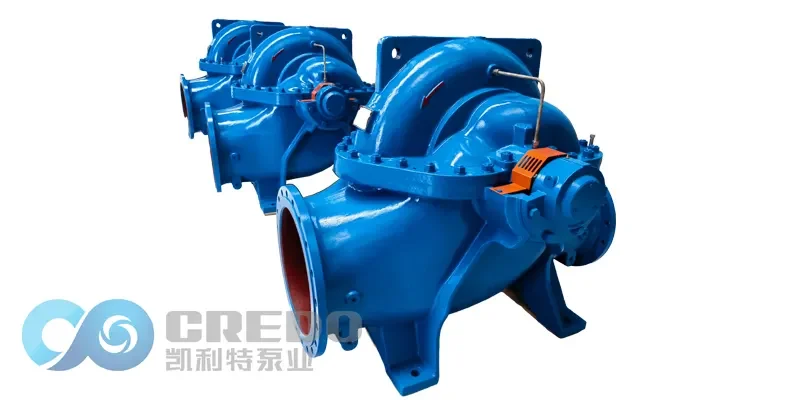

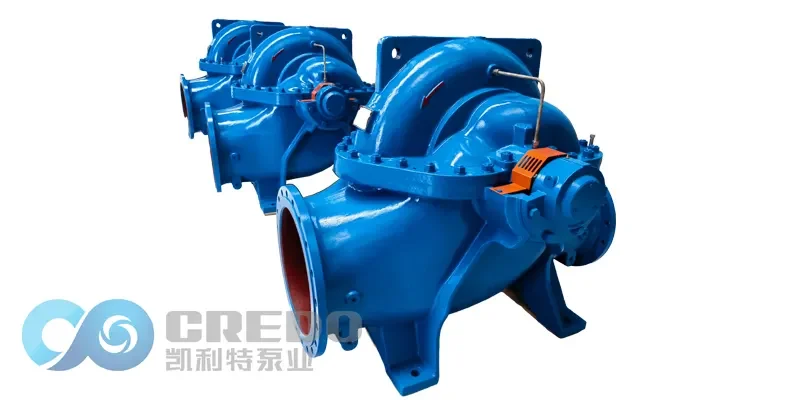

How to Diagnose and Reduce Cavitation Damage in Split Case Pumps

Cavitation is one of the most common and destructive hydraulic problems affecting split case pumps. It occurs when local pressure in the fluid drops below its vapor pressure, causing vapor bubbles to form and collapse violently near the impeller or suction region. These micro-collapses generate high-energy shock waves that result in pitting, vibration, noise, erosion, and premature component failure.

For pumps already in service, early diagnosis and practical mitigation measures are essential to reduce damage and extend equipment life. This article summarizes effective cavitation diagnosis methods and field-proven solutions to reduce cavitation in operating split case pumps.

1. Cavitation Diagnosis Methods for In-Service Split Case Pumps

In field conditions, users often cannot perform factory cavitation tests (such as head-drop testing at constant flow). Therefore, practical diagnostic methods are widely used, often in combination.

Table 1: Comparison of Cavitation Diagnosis Methods

| Method | Principle | Advantages | Limitations | Typical Application |

| Observation | Visual inspection of impeller and casing surfaces | Direct and intuitive | Post-damage only | Failure analysis |

| Noise | Detects crackling or bursting cavitation sounds | Simple, non-intrusive | Strongly affected by ambient noise | Severe cavitation |

| Vibration | Measures vibration frequency changes | Easy to deploy | Low sensitivity; masked by other faults | Supplementary use |

| Ultrasonic | Detects high-frequency signals from bubble collapse | High sensitivity, early detection, real-time monitoring | Requires sensors | Best for early-stage detection |

Engineering Note: Ultrasonic detection is the most reliable method for early cavitation diagnosis and is well suited for integration into SCADA or condition monitoring systems.

2. Practical Methods to Reduce Cavitation During Operation

Once cavitation is identified, mitigation should focus on improving suction conditions, reducing inlet losses, and increasing NPSHa.

Table 2: Operational Measures to Reduce Cavitation in Split Case Pumps

| Improvement Area | Practical Measure | Cavitation Reduction Mechanism | Implementation Difficulty |

| Inlet tank design | Install vortex breakers, increase submergence | Prevents air entrainment | Low |

| Suction piping | Shorten pipe, reduce bends, enlarge diameter | Reduces suction losses | Medium |

| Inlet pressure | Ejector system, booster pump, pressurized tank | Increases NPSHa | Medium–High |

| Pump selection | Double-suction split case pump | Improves inlet flow symmetry | Medium |

3. Supplying Air into the Suction Line

Introducing a controlled amount of air into the suction line does not eliminate cavitation but can reduce erosion damage to flow passage walls. The air cushions the collapse of vapor bubbles, similar to methods used in hydraulic turbines.

Limitations:

This technique is rarely applied to split case pumps because air flow rate and injection location are difficult to control. Improper air supply can significantly reduce pump head, flow, and efficiency.

4. Use of Anti-Cavitation Materials

Material selection plays a key role when cavitation cannot be fully avoided.

Table 3: Cavitation Resistance of Common Pump Materials

| Material Type | Cavitation Resistance | Typical Application |

| Cast iron | Low | Non-critical services |

| Bronze / copper alloys | Medium | Mild cavitation |

| Stainless steel | High | Cavitation-prone systems |

| Cr-Ni alloy steel | Very high | Severe cavitation environments |

Best Practice: Replacing cast iron or copper components with stainless steel or Cr-Ni alloy steels can significantly improve durability in cavitating services.

5. Impeller Surface Protection Methods

Applying protective layers to impellers is a widely used and effective approach.

Table 4: Impeller Protection Technologies

| Method | Advantages | Drawbacks | Durability |

| Epoxy / polymer coating | Low cost, easy application | Peeling over time | Low |

| Stainless steel surfacing | Good protection | Moderate cost | Medium |

| Alloy overlay welding | Strong adhesion | Skilled labor required | High |

| Alloy powder spray welding | Best cavitation resistance | Higher cost | Very high |

6. Trimming the Impeller Head

Impeller trimming is a proven hydraulic modification technique. By reshaping and thinning the blade tip near the inlet, local pressure and velocity peaks are reduced. This lowers vapor bubble formation at the blade leading edge and decreases cavitation intensity.

Conclusion

Cavitation damage in split case pumps can be significantly reduced through a combination of diagnostic and mitigation measures rather than a single solution.

Key Guidelines:

Ensure installation height is within allowable suction limits

Keep suction piping short, straight, and free of air pockets

Avoid undersized suction pipes and unnecessary fittings

Monitor noise, vibration, pressure, and temperature during operation

Apply cavitation-resistant materials or surface treatments when needed

Through proper diagnosis, optimized hydraulic design, material upgrades, and proactive maintenance, users can effectively control cavitation, improve reliability, and extend the service life of split case pumps.