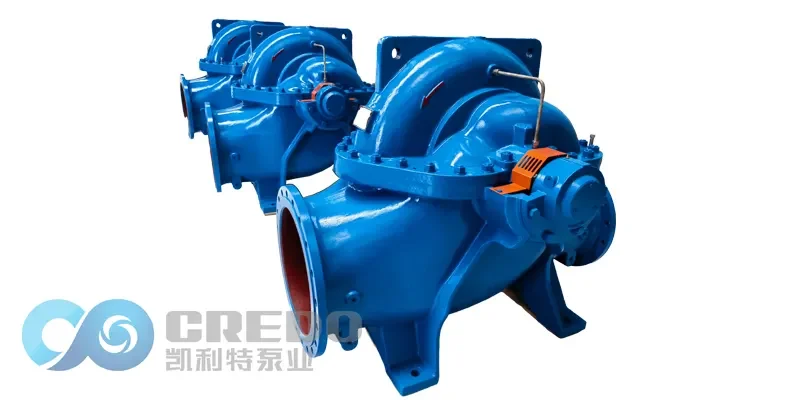

Exploring the Working Principle and Advantages of the Split Case Double Suction Pump

The split case double suction pump is a high-performance centrifugal pump commonly used in municipal water systems, industrial processes, irrigation, and cooling applications. Compared to the traditional single suction pump, the double suction design offers superior flow capacity, reduced vibration, and enhanced stability. This article will explore the differences between single and double suction pumps, explain how a split case double suction pump works, and discuss its advantages in various application environments.

Single Suction vs. Split Case Double Suction Pump: What’s the Difference?

Understanding the structural and operational differences between pump types is key to selecting the right pump for your system.

Comparison Between Single Suction Pump and Split Case Double Suction Pump

| Feature | Single Suction Pump | Split Case Double Suction Pump |

| Suction Port Design | One suction port | Two symmetrical suction ports on both sides of the impeller |

| Flow Direction | Fluid enters the impeller from a single direction | Fluid enters the impeller simultaneously from both directions |

| Hydraulic Balance | Axial forces are higher due to single-side flow | Axial forces are largely balanced, reducing bearing load |

| Flow Capacity | Suitable for low to medium flow applications | Ideal for high flow applications |

| Efficiency | Moderate efficiency | Higher hydraulic efficiency |

| Vibration Level | Higher vibration risk at large flow rates | Reduced vibration and smoother operation |

| Typical Applications | Small water supply systems, HVAC, light industrial use | Municipal water supply, power plants, irrigation, large industrial systems |

| Overall Design | Simple structure, easy to manufacture and maintain | More complex design, optimized for stability and long-term reliability |

Can a Split Case Double Suction Pump Deliver Double the Flow?

Yes, under equivalent conditions, a split case double suction pump can achieve nearly double the flow of a single suction pump with the same impeller outer diameter. This is because the symmetrical design allows fluid to enter the impeller from both sides, effectively doubling the volumetric intake without increasing impeller speed or size. This advantage makes the double suction design highly desirable for systems requiring high throughput without excessive energy consumption.

Working Principle of a Split Case Double Suction Pump

The operational efficiency of a split case double suction pump lies in its centrifugal mechanism combined with a balanced, dual-entry impeller structure. Here’s how it works:

| Stage | Description |

| 1. Structural Design | • The pump features a centrally positioned impeller with suction inlets on both sides • The impeller is enclosed in a horizontally split casing, allowing easy maintenance and inspection • Symmetrical suction design reduces axial thrust and ensures balanced, stable operation |

| 2. Fluid Intake | • When the pump is started, the motor drives the impeller to rotate • Fluid is drawn into the pump simultaneously through both suction ports, entering the impeller from opposite directions • Dual-side intake minimizes turbulence and stabilizes internal flow |

| 3. Centrifugal Action | • As the impeller rotates, centrifugal force drives the liquid from the impeller center toward the outer periphery • The fluid gains velocity and kinetic energy during this outward movement |

| 4. Discharge and Pressure Generation | • The energized fluid exits the impeller and enters the volute casing • Pressure increases as velocity is converted into pressure energy, enabling fluid delivery to higher elevations or over longer distances • The discharge outlet is typically positioned at the top or side of the casing |

Key Advantages of Split Case Double Suction Pumps

Split case double suction pumps offer several performance and operational benefits:

| Advantage | Description |

| High Flow Efficiency | • Delivers higher flow rates at lower operating speeds compared to single suction pump designs • Ideal for applications requiring consistent and high-volume fluid transfer |

| Reduced Vibration & Improved Stability | • Symmetrical fluid entry reduces axial load on the shaft and bearings • Lower vibration levels extend pump service life and reduce maintenance frequency |

| Easy Maintenance | • The split case construction allows the pump to be disassembled without removing inlet or discharge piping • Simplifies inspection, servicing, and replacement of internal components |

Applications of Split Case Double Suction Pumps

Thanks to their efficiency, durability, and versatility, split case double suction pumps are used across a wide range of industries:

| No. | Application Area | Description |

| 1 | Municipal Water Supply | Distributes clean water for residential, commercial, and industrial users |

| 2 | Industrial Water Treatment | Handles raw water intake and treated wastewater discharge in treatment facilities |

| 3 | Cooling Systems | Transfers cooling water in power plants and various process industries |

| 4 | Agricultural Irrigation | Provides reliable water delivery for large-scale farming and irrigation projects |

| 5 | Fire Protection Systems | Supplies high-pressure water for fire suppression systems in buildings and industrial zones |

| 6 | Chemical Processing | Safely and efficiently transports corrosive or high-pressure liquids |

| 7 | Mining and Quarrying | Used for dewatering and water supply in harsh and rugged operating environments |

| 8 | HVAC and Air Conditioning | Circulates chilled or cooling water in large commercial and industrial HVAC systems |

Conclusion

The split case double suction pump is a powerful, efficient solution for systems requiring high flow rates with minimal vibration and operational stress. Its dual suction design not only increases capacity but also ensures long-term reliability and performance. By understanding its working principles and application advantages, users can make more informed decisions when selecting pumps for complex industrial, agricultural, or municipal systems. For maximum efficiency and system stability, a split case double suction pump is often the optimal choice.