Zoned Water Supply for Diesel Engine Fire Pumps: When and Why It Matters

1. Introduction

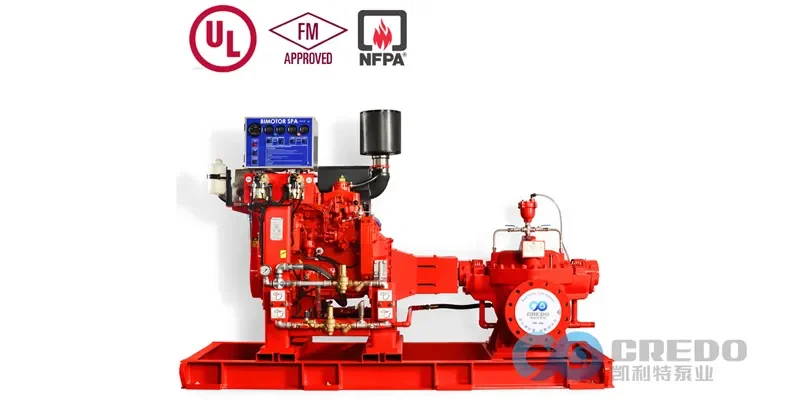

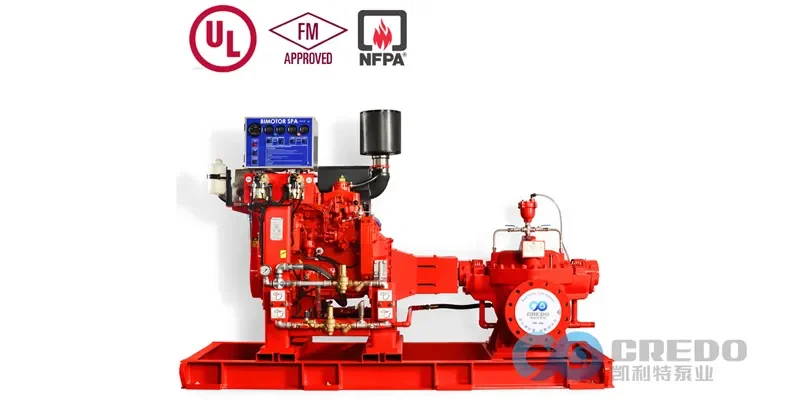

Diesel engine fire pumps play a vital role in fire protection systems, especially in critical infrastructure or high-rise buildings. They are not only responsible for delivering water under emergency conditions but also ensuring that the water pressure remains within safe and operational limits. In complex systems, zoned (partitioned) water supply becomes essential to avoid overpressure risks and enhance system efficiency.

2. Why Zoned Water Supply Is Necessary

The main purpose of implementing a zoned water supply system in diesel fire pump configurations is to control excessive water pressure. In large or vertical structures, static and dynamic water pressure can exceed safe operating limits. This can lead to:

– Pipe and joint damage due to overpressure;

– Failure of valves and sprinkler heads;

– Unnecessary energy consumption from over-pumping;

– Unsafe working conditions for fire suppression components.

By dividing the system into zones, each section can operate within an optimal pressure range.

3. Conditions That Require Zoned Supply

Zoned or partitioned water supply should be considered when any of the following pressure thresholds are exceeded:

– System working pressure is greater than 2.40 MPa;

– Static pressure at the diesel fire pump outlet exceeds 1.0 MPa;

– Working pressure at the alarm valve in an automatic sprinkler system exceeds 1.60 MPa, or the nozzle pressure is greater than 1.20 MPa.

Meeting these conditions indicates that the system may be at risk of excessive stress and should be restructured into pressure-managed zones.

4. Implementation Methods for Zoned Water Supply

Several technical approaches can be applied to implement zoned water supply in diesel engine fire pump systems. The best method depends on system layout, building height, and economic and safety considerations. Options include:

– Series Pump Systems: Using multiple fire pumps in series to manage pressure across zones.

– Pressure-Reducing Tanks: Tanks designed to absorb and stabilize excess pressure between sections.

– Pressure-Reducing Valves (PRVs): Installed at strategic points to regulate pressure before water enters a lower-pressure zone.

When system pressure exceeds 2.40 MPa, it is strongly recommended to use either series-connected diesel fire pumps or pressure-reducing tanks to maintain safety and functionality.

5. Key Design Considerations

Designers must evaluate the following when planning a zoned water supply:

– Building characteristics (height, usage, fire risk level);

– System hydraulics (friction loss, elevation head, residual pressure);

– Economic feasibility (equipment and installation cost);

– Safety & reliability (fail-safe design, maintenance accessibility).

In high-rise fire suppression systems, zoning is not only a recommendation but often a regulatory requirement (refer to standards such as NFPA 20 or GB 50016).

6. Conclusion

Zoned water supply systems for diesel engine fire pumps offer significant advantages, including:

– Pressure control and system safety;

– Improved energy efficiency;

– Extended lifespan of fire protection components.

However, zoning must be applied under specific conditions and supported by proper design strategies to ensure effective and reliable fire protection. Understanding these zoning principles is crucial for engineers, facility managers, and fire protection professionals looking to optimize performance in high-pressure environments.